5 Packaging Mistakes That Destroy International Shipments (And How to Avoid Them)

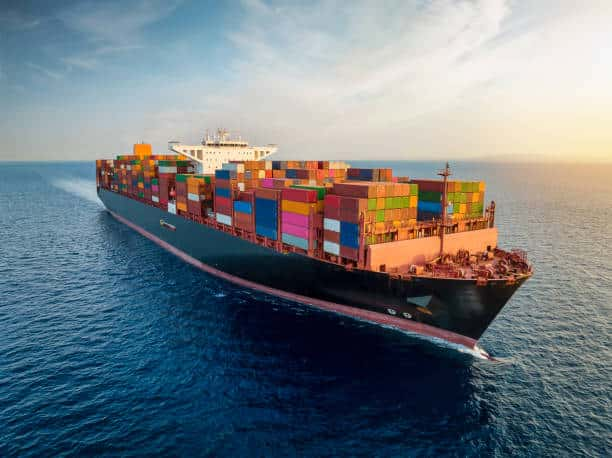

Your shipment just survived 30 days at sea, thousands of miles across oceans, only to arrive damaged. In most cases, the problem didn’t start during transit – it started with how your goods were packed.

After handling thousands of containers, we’ve identified the packaging mistakes that cause the most damage. Here’s how to spot them and protect your shipments.

Mistake #1: Using Weak or Single-Wall Boxes

The Problem:

Standard office-grade cardboard collapses under the weight of stacked containers. International shipping involves stacking up to 8 containers high – that’s immense pressure.

The Solution:

Use double-wall corrugated cardboard for anything over 15 kg

For heavy items (30+ kg), upgrade to triple-wall boxes

Look for boxes with an ECT (Edge Crush Test) rating of at least 44 lb/in

Mistake #2: Poor Internal Bracing

The Problem:

Products shifting inside containers during ocean transit cause:

Impact damage from constant movement

Container walls taking direct hits

Other goods in the container getting damaged

The Solution:

Fill empty spaces with inflatable air bags

Use corner protectors for furniture and machinery

Install wooden bracing for heavy equipment

Don’t rely on packing peanuts – they settle and create gaps

Mistake #3: Ignoring Humidity and Temperature Changes

The Problem:

Containers traveling from humid to cold climates experience “container rain” – condensation that drips onto your goods and causes:

Mold growth on textiles and furniture

Rust on metal components

Water damage to packaging

The Solution:

Use silica gel desiccant bags (calculate 500g per cubic meter)

Wrap moisture-sensitive items in plastic first

Consider humidity-controlled containers for high-value goods

Use moisture barrier bags for electronics

Mistake #4: Incorrect Pallet Loading

The Problem:

Poorly loaded pallets collapse during handling, causing:

Forklift accidents at ports

Stacking failures in container yards

Individual boxes getting crushed

The Solution:

Use interlocking patterns when stacking boxes

Don’t build pyramid shapes – keep loads vertical

Secure with high-quality stretch wrap (at least 5-7 layers)

Make sure pallets can be accessed from all four sides

Mistake #5: Inadequate Labeling

The Problem:

Faded, small, or missing labels lead to:

Mishandling of fragile goods

Delays in customs clearance

Packages getting lost in terminals

The Solution:

Use waterproof labels with international symbols

Include handling instructions in multiple languages

Place labels on at least two sides of each carton

Use contrasting colors for special instructions

Quick Packaging Checklist for Your Next Shipment

For All Shipments:

Double-wall corrugated boxes

“Fragile” and “This Side Up” labels on all sides

Adequate void fill material

Proper shipping documentation attached

For Container Loads:

Moisture protection measures

Proper pallet configuration

Container inspection before loading

Weight evenly distributed

For Special Goods:

Anti-static packaging for electronics

Climate protection for wood products

Custom crating for irregular shapes

Vibration isolators for machinery

The Cost of Getting It Wrong

One client learned this lesson the hard way: their $25,000 furniture shipment arrived with 40% water damage because they used standard boxes without moisture protection. The repair bill exceeded $8,000 – all preventable with proper packaging.

Good packaging isn’t an expense – it’s insurance. The small additional cost of proper materials prevents massive losses down the line.

Related Posts

20-foot / 40-foot container ocean freight

20-foot / 40-foot container ocean freight Tired of sticker shock…

Shipping Lithium Batteries: Complete Compliance Guide

Shipping Lithium Batteries: Complete Compliance Guide Shipping lithium batteries requires…

FOB to DDP Shift: How Manufacturers Slash 18% Total Export Costs (Step-by-Step Guide)

FOB to DDP Shift: How Manufacturers Slash 18% Total Export…